When we talk about the most impactful technologies of today that have a very bright future, 3D scanning technology indeed deserves a mention. 3D scanning technology provides an innovative approach to digitally capture the shape of a physical object by creating “point clouds” of data from the surface. Despite being in its initial stages, this technology is enabling advances in science, education, medicine, education, manufacturing, and many more, in fact, it is becoming part of our lives at a much faster pace than expected. As per some latest market research reports, 3D scanning is predicted to grow at an annual compounded growth rate of 9.6% until 2022 and by the year 2025, the global 3D scanning market will be approximately USD 8.04.

Now, the important thing to understand here is how exactly this impactful 3D scanning technology is proving beneficial, what are its scope, limitations, common uses, and other aspects.

Advantages of 3D Scanning Technology

Various industries including automotive, aerospace, medical, and manufacturers are making optimum use of the 3D scanning technology for inspection of parts, accurate measurement, and other purposes. Depending on the type of scanner being used, 3D scanning technology offers immense benefits in terms of saving time and resources. Also, it can be used for recreating designs and parts that do not exist. In other words, it can be used to reverse engineering a new part that may no longer be available in the market. Other than this, the exact replacement parts can be created using 3D scanning technology. The added advantage of this revolutionary technology is in the health sector.

The technology can help in quickly capturing all of the physical measurements of any physical object, ensure the parts are designed so accurately that they can fit together in the first go. Besides, it can help in capturing engineering optimizations inherent in manufactured parts. It can also be utilized for modern manufacturing on parts that were originally manufactured before CAD and comparison can be made between as-designed models to the as-built condition of manufactured parts.

The Challenges

Although 3D scanning technology can be used in various fields, there are certain challenges that come with it. Lighting, for example, is one of the main criteria for 3D scanning. If the lighting is either less or too much, it can prove to be a hindrance. Another factor that can prove to be challenging is proper knowledge and understanding of how technology can be used to get the best results. The 3D technology can be used in various fields, so proper training is required for making optimum use of the technology.

Keenly interested in knowing about 3D digitizing with the power of laser i.e. 3D laser scanners, theirs uses, limitations, and to get insight into more about laser 3D scanning technology, we sat down with Adrian Schipor, 3D Laser Scanning Technology expert and asked him about the same. Here is what he said:

“There are various aspects of 3-D laser scanning technology. The laser scanners are capable of capturing millions of points and create a 3D map (black and white or colored) in a matter of just a few minutes. Different laser scanners have different accuracies depending on the task they assigned for. You can use these scanners indoors or outdoors. However, it becomes a bit challenging when it is raining. The range of the laser scanning beam varies from instrument to instrument. Let's say from 0m to 70m from 0m to 130m and 0m to 330m.

3D laser scanners can be operated by 1 person with ease, are fully automated, once you press the "scan button" all you have to do is wait a couple of minutes and move the instrument's position/location and carry on. The 3D laser scanning technology can be used in architecture, restoration works, preservation through 3d mapping, to create gaming environments, to create accurate 3d maps and index them to Google earth, and other mapping apps, in the construction industry (for monitoring different phases during the construction process), etc. Also, police can use it for car accident investigations.

Simulations, scenarios based on repetitive data capturing, like monitoring a building during different phases can be easily created with the help of the 3d laser scanners. Besides, you can simply create 1:1 scale scans that can be used for 3d printing. You can scan literally everything, apart from water mirrors and reflective objects. These can be used in dental medicine and so many more areas. The future if this technology is undoubtedly limitless, it's versatility is just amazing. By using laser scanning, you can speed up processes. The instrument size, scanning time, and the hefty price tag it comes with are the limitations of 3d laser scanning technology. But that's improving while we speak”

What if Artificial Intelligence is added to the 3D Scanning?

Combining Artificial Intelligence with the 3D scanning brings in greater potential in situations where subjective decisions are needed to be taken. The NVIDIA Jetson supercomputer technology is making use of 3D scanning.

With AI-based 3D scanners, subjective decisions using set parameters can be taken with ease. 3D scanning is helping aviation sectors to detect dents if any, and with the use of AI, it would be easy to decide if the issue needs to be addressed in the immediate future. Large-scale adoption and solutions that are the result of 3D scanning and AI are improving the accuracy and lessen down the number of hours that it would take otherwise.

Where is the 3D Scanning Technology Being Used? /Who can benefit from 3D scanning Technology?

3D scanning technology is becoming ever more popular throughout industries all over the world. From designing to being used in the prototype phase, engineering, production, quality control, distribution; the 3D scanning technology can prove to be advantageous in various sectors. With advantages like precision, ease of use, and versatility it offers, it can be used in various sectors like healthcare field, education, manufacturing, etc. Companies like Boeing, NASA, Navantia, General Electric, Nike, Hershey, and many more are currently making optimum use of 3D scanning. Let us take a look at which sectors/fields are being benefited the most from the technology.

In the Healthcare Sector:

It can be used to take accurate measurements of patients in instances where the prosthetic limb is to be created or in case a child has fractured an arm, the 3D scanning technology will take the measurement quickly without forcing the child to sit in a fixed position for long. By being able to accurately and precisely scan a missing limb, researchers can create exact replicas which can prove to be time and money-saving.

In Phoenix, Arizona, an alligator (named Mr. Stubbs) was found without a tail. Researchers from Midwestern University and the Phoenix Herpetological Society in conjunction with Stax 3D used 3D scanning and 3D printing and crafted a prosthetic tail for the alligator.

Interacting with Digital Models and Studying Artifacts:

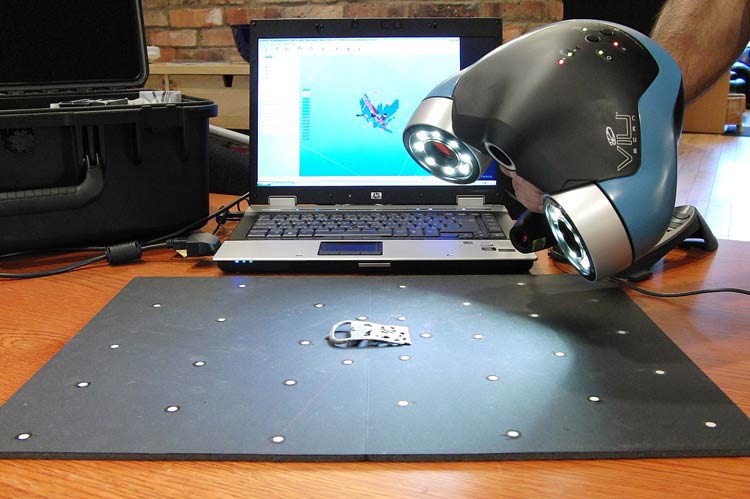

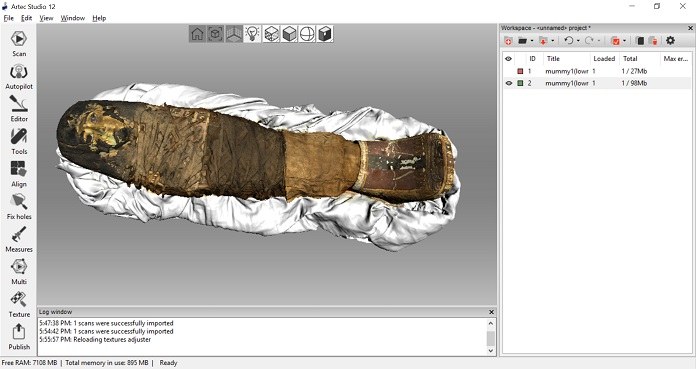

3D scanning technology can be used to keep a check on precious, historical artifacts that cannot be touched or removed easily for examination and studying. 3D scanning can help create a digital model that can be studied. An example of 3D scanning being practically used when 3D scanning was used to make it possible for people to virtually interact with objects/artifacts. The technology helped in creating a digital model of the Sherit mummy at the Rosicrucian Egyptian Museum in San Jose, California. Another example where 3D scanning technology proves useful is in scanning a unique fossil, or any other subject without any fuss. The 3D model of the Sherit mummy was created with an Artec Eva 3D scanner that was rendered in Artec Studio 12 software.

In the field of Education:

3D Scanning technology is being used by students to get a better understanding of history, design, and art. Students at Mid-Pacific Institute in Hawaii used the 3D-scanning technology to create a virtual museum as part of their coursework. The revolutionary technology is offering an interactive and modern way for students to learn about the artifacts. 3D scanning technology is also proving useful in preserving precious artifacts.

In the field of medicine:

3D scanning technology can be used to create virtual cadavers for students to study and use. At the Montpellier Medical University in France, medical students were facing a shortage of cadavers to learn about dissections. 3D scanning came as a rescue and the professors of the university started using the technology to accurately capture all dissection stages, and provide 3D photorealistic models thereby creating a realistic virtual cadaver for the students for dissections.

3D Scanning Technology: Expectations

Seeing the present scenario as to how 3D scanning is proving useful in different sectors, we can ascertain that it has a bright future ahead and almost every sector is likely to benefit from the technology in the years to come.

Increasing Learning Opportunities:

3D technology can help open the doors of the museum. How? Empowering museum professionals in analyzing the internal structure of the objects easily, the doors of museums can open up for learning opportunities for the students and professionals for exploration. Besides, it will enable visitors to download and print objects in the museum. This definitely will enhance awareness and help people get crucial information for projects and research work.

Boom for Manufacturing Sector:

3D scanning can be used in the very initial phases of designing in the form of CAD files. The 3D models help in improving the accuracy of the design. Various industries can make optimum use of the 3D scanning to try various versions of the same design on the computer before finalizing the design. This definitely will reduce the cost and amount of rework it would have otherwise required if done physically time and again to get the best results.

The scanners can capture the physical measurement of an object accurately and help to generate CAD files effortlessly. Also, the comparison between designs becomes easier. This definitely is going to prove boom to manufacturing industries.

Quality Control:

3D scanning is playing a vital role in quality control and the number of industries adapting to the technology is likely to increase in the future. The AI with 3D technology as we have discussed is the thing that companies can easily rely on, increase investment by integrating artificial intelligence, and take crucial subjective decisions. In the days to come, AI with 3D scanning will be used to teach computers to make decisions based on specific criteria. Also, these two technologies can help in inspecting dent in airplanes, measuring impressions, thereby, helping in taking decisions if the immediate action is required or not. The quality control is one main area where 3D scanning can prove to be quite successful. Automating quality control with the help of 3D technology has led to the reduction in human error and labor hours, thereby, directly impacting the expenses and increasing the flexibility in quality control.

Future of 3D Scanning

It’s not been long since we have been introduced to 3D scanning technology and it is advancing at a very high pace. With each passing day, we study about the use-cases for 3D scanning. Getting in-depth knowledge about the benefit, limitations gives us a clear insight into what we can expect in the years to come. We have talked in length about how incorporating AI to this technology is going to make the process more intuitive and convenient. We can now say that the future of 3D is far brighter than we can imagine. AI will be a cherry on the cake and will make 3D scanning as easy as taking video with a cell phone. The use of 3D scanning is sure to increase multi-folds in the years to come and we can be sure that the technology is indeed going to become the necessity for various industries.

Having said that, we know that with the advancement of this technology, it is going to help industries and various sectors push the boundaries and help them make advancement in various forms. 3D scanning technology is soon going to become a vital part of our day-to-day life.