Panasonic India feels that India has a huge potential in building smart factory solutions and SMT manufacturing will be the key connecting factor here.

The demand of SMT equipment is gaining traction

Over the past couple of years, technology has been progressing on a rapid scale, its demand has also augmented among various industrial sectors and consumers. Across the vast consumer electronics cluster, which comprises smartphones, tablets, computers, liquid crystal displays (LCD), and LEDs, the utilization of Printed Circuit Boards (PCBs) has escalated tremendously. According to several electronics associations such as IESA and ELCINA, the market share of consumer electronics is much higher than that of industrial electronics. Hence, placement and soldering equipment is being largely utilized in the manufacturing of numerous electronic products, which in turn has increased the applications and demand of surface mount technology (SMT) machineries. As the adoption and market of industrial and smart electronic devices have increased, the cleaning market of SMT has also evolved because during the production process, there is a much requirement for cleaning equipment. Currently, the form factor of electronic devices has contracted due to which soldering equipment has been outstripped by SMT placement equipment in terms of market share.

An overview of SMT manufacturing in India

Over the past seven to eight years, India has witnessed unprecedented growth in the electronics segment whose manufacturing is also growing every year. Carefully examining the policy front, the government of India has escalated the rate of custom duties on the import of PCBs and other manufacturing components in order to encourage manufacturing locally. Due to this, domestic manufacturers will be forced to manufacture and assemble PCBs in India. Now, if manufacturing starts happening locally, then the momentum of growth of the country's SMT industry would also perk up rapidly.

While speaking of the imperativeness of manufacturing in the country, Sandeep Aurora, Vice President – Business Development & Govt Affairs, IESA told an online media, “We need to address the entire manufacturing and supply chain procedure in the nation so that we can become ‘atmanirbhar’. To fulfill that dream, SMT manufacturing must be the top priority, maybe not instantly, but surely has to be carried out, and then only India would be able to enhance the strength of its entire electronics manufacturing cluster.”

On the other hand, India’s industry experts opine that the government has to understand the importance of SMT manufacturing, and then only there can be momentum in India’s electronics manufacturing. The machine’s manufacturing has already commenced well, but there should be more push to the government’s ‘Vocal for local’ policy’ that will push the growth to a larger extent. Currently, it is predicted that the SMT segment in India would witness a growth rate of 20-25 percent every year until 2025 if the plan works successfully.

Speaking of the various challenges of SMT manufacturing in India, Masafumi Himeno- Div. Managing Director – PSFSIN, Panasonic India said exclusively to CircuitDigest, “SMT manufacturing has a history of more than 50 years, in terms of equipment, human resources, and management. It has undergone various major evolutions. In addition, SMT manufacturing (production area) is expanding globally. India must achieve complete non-defective production. Under the Make in India policy, the future of SMT manufacturing in India is bright. India is still a young market in electronic manufacturing compared to other countries. Therefore, to achieve complete non-defective production and to build an experienced workforce will take some more time, but I believe these challenges will be overcome in near future.”

Praveen Madan, GM, SMT Division- Juki Singapore told CircuitDigest, "It is always the quality and cost of the end-product. As of today, 80-90% of the parts / raw materials are imported and most of the SMT products manufacturing is for the domestic market in India. Higher import means higher cost. In India, labor cost could be cheaper compared to other countries, but capital goods, cost of operation, and inefficiency in factory utilization could be higher due to various political or regional reasons. These are the vital problems that need to be fixed before thinking of fulfilling the dream of making India a global manufacturing hub including SMT.”

Where does the SMT market stand amid pre and post COVID-19

Market situation is now to wait and watch due to the higher cost of manufacturing. People are worried about the 3rd wave of COVID -19 and cannot predict the lockdown. Many customers have delayed their new projects and investments.

If India wants to become a global SMT manufacturing hub, then some of the following need to be considered:

- 04 Electronics Manufacturing clusters in each region for complete supply chain

- Give incentives to manufacturers per PC export. For example, if one LED TV made in India is being exported, then they can get a fixed value from the government, say per PC export.

- Need to change the mindset for export orientation (this includes quality, price, delivery, and after-sales support globally)

- Need more PCB and component manufacturing plants. Since the cost of setting up a semiconductor plant is high, govt participation is important in terms of investment to start with.

- Global branding/promotion of Make in India products.

“Due to the pandemic, SMT manufacturing industry, just like others, was temporarily affected. However, factors such as semiconductor shortage, low demand, and availability of workforce are for the interim period, and we don’t see an impact on the industry over the long term. On the positive side, the pandemic has hastened the digitization process. Faster adoption of digital will lead to an increase in demand for Automation, Automated Guided Vehicles(AGVs), software solutions, preventive maintenance, and digital reporting features, post-pandemic” added Himeno.

India is already on the path of becoming a global manufacturing hub, some of the additional factors that will help foster the growth are:

- Contract manufacturing and Electronics Manufacturing Services

- Long term and stable policies

- Ease of doing business

- Export incentives

- Creation of SEZs

- Optimizing supply chain efficiencies

- Incentivize schemes like PLI

- Creation of skilled workforce

Growth of SMT market in India

The SMT market in India is expected to reach a turnover of US$ 5.42 billion by 2022, growing at a CAGR of 8.9 % between 2017 and 2022, claims a report by research firm Markets and Markets. The growth of this market would be fuelled by the increased adoption of miniaturised consumer electronic products and the augmented demand for electric vehicles coupled with sophisticated features for connectivity, safety, and entertainment.

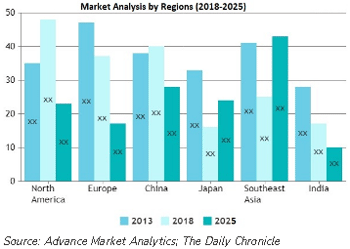

India’s industry experts feel that the country still lags behind having a state-of-the-art electronics manufacturing service (EMS) industry; the speculated volume of the Indian SMT equipment industry would be about 75 – 80 percent of the EMS industry. As per industry estimates, Indian SMT market is expected to grow in double digits. MeitY industry report estimates that the global SMT market is expected to grow by 5-7% CAGR during ‘20-’25.