Weeks after Shri Narendra Damodardas Modi became the Prime Minister of India in May 2014, a meeting has been summoned by the PM in Vigyan Bhawan for discussing key development strategies and the roadmap for India. While discussing the current policies and strategies, the PM also urged for Making products in India. In fact, separate funds and campaigns must be done to boost the industrial sectors in India. After highlighting all the sectors, the PM urged to formulate separate policies and form investment plans to bolster the electronics and semiconductor ecosystem in India. Quoting the impact of growing the electronics industry, the PM said that along with developing other social issues, there is a requirement to grow this sector and make it globally competitive as it has the huge potential to contribute in macroeconomics. This is when full effort and initiatives have been undertaken by the government to grow the industry. In the middle of the digital revolution, there is a requirement for all the nations to grow and boost their electronics manufacturing ecosystem. “Make-in-India”, “Aatmanirbhar Bharat”, and “Vocal for Local” are some the campaigns that elevated the confidence among the indian electronics companies to produce goods locally for domestic consumption and exports.

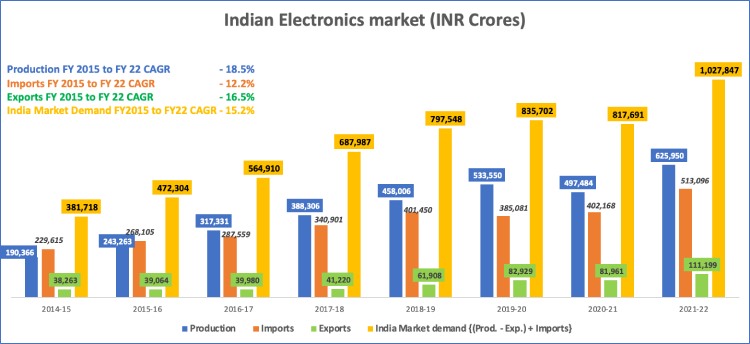

Speaking of India's growth in export and production in the ESDM sector, exports of electronic goods reached Rs 41220 crores, and production reached Rs 388306 crore in 2017 as per a report by the government. By 2022, exports reached Rs 109797 crore and production had reached Rs 6,40,810 crore. Speaking of macroeconomics, in the financial year 2022, the contribution of domestic production value of electronics to Indian GDP was about 2.7 percent. This contribution share was estimated to increase to 4.7 percent by the financial year 2026 in the country.

In a very short span of time, the government in association with the industry bodies and the manufacturers has changed the dynamics of the electronics manufacturing ecosystem. It is growing at such a rapid pace, the government has now set a target of $300-$400bn worth of total production by 2026. Have you ever imagined why the entire world is now undertaking efforts to boost this sector? It is event that COVID-19 has spurred the demand of electronics and semiconductors all over the world, but demand has already augmented with the proliferation of the internet and increased pace of digitization. Hardly, there are any industrial sectors that can survive without electronics. From smart home to automobiles, FMCG, and other sectors, electronics have dominated most of the industrial sectors. This industry has the potential to contribute massively to the GDP of a country.

Policies and Schemes That Redefined India’s Electronics Manufacturing Ecosystem

After several rounds of discussions in regards to growing the industry, the then government and the industry bodies like ELCINA has formulated the first policy in 2012 directed towards growing the electronics industry in India, dubbed National Policy on Electronics (NPE). Under its aegis, Electronics Manufacturing Cluster EMC 1.0 was formed. Although it’s termed as the most comprehensive policy formulation, the NPE 2012 failed to attract big-ticket investments, seed high value-added manufacturing in the India ESDM ecosystem, or create large-scale employment, according to the Economic Times report by Rajoo Goel, Secretary-General of ELCINA. According to R. Swaminathan’s report, NPE 2012, comes on the back of a strong and sustained demand for consumer electronic goods that accounted for a hefty bill of US$125 billion. However, just about 10 percent of India's consumption was produced internally; the rest was imported.

Can a nation bolster electronics manufacturing at large-scale without developing the components ecosystem? Although the electronics industry is being developed at various fronts, the country still outsources 80 percent of components and raw materials from China and other countries. The industry bodies and the manufacturers have constantly stressed the importance of developing components and the semiconductor ecosystem. After several years of NPE 2012, the government revised the policy in 2019 and under its aegis launched the much-appreciated Production Linked Incentive for 14 sectors worth Rs. 197 lakh crores.

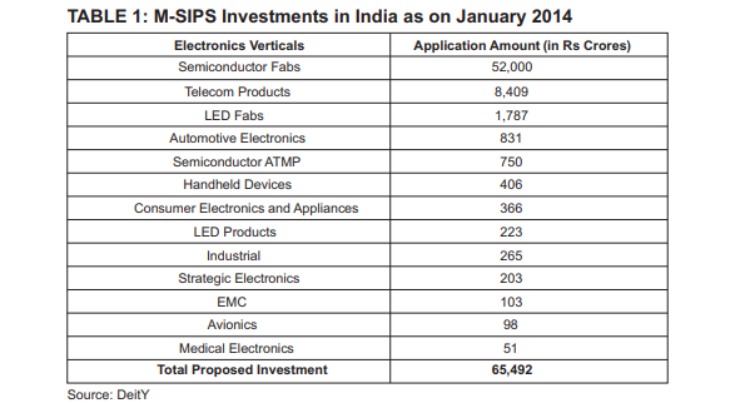

Under NPE 2019, Modified Special Incentives Scheme (M-SIPS), Electronics Manufacturing Clusters (EMC), and Scheme for Promotion of Manufacturing of Electronic Components and Semiconductors (SPECS) have been announced to boost the industry. In fact, the Aatmanirbhar Bharat campaign initiated during the pandemic in 2020 also played a key role in motivating manufacturers to make products in India and highlighted the imperativeness of self-reliance in electronics manufacturing. This is when Foxconn, Pegatron, and Wistron, now acquired by Tata, started producing Apple’s iPhones in the southern part of India.

The Scheme for Promotion of Manufacturing of Electronic Components and Semiconductors (SPECS) was notified on 1st April 01, 2020. The SPECS Scheme provides financial incentive of 25% on capital expenditure for the identified list of electronic goods that comprise downstream value chain of electronic products, i.e., electronic components, semiconductor / display fabrication units, ATMP units, specialized sub-assemblies and capital goods for manufacture of aforesaid goods. .Over the tenure of SPECS Scheme, the expected new investment in Electronic Components and sub-assemblies was Rs 20,000 crore. The total employment potential of the scheme was approximately 6,00,000 (1,50,000 direct employment and 4,50,000 indirect employment). Under this scheme, around 32 companies have been selected and given incentives.

Then, in an effort to create a world class infrastructure, the government again revised the original Modified Electronics Manufacturing Clusters in 2020, dubbed EMC 2.0. Under EMC 2.0 scheme, 3 EMC applications covering an area of 1,337 acres have been approved with project cost of Rs 1902.69 crore including financial assistance of Rs 889.02 crore from Government of India. These EMCs are poised to attract an investment of about Rs 20,910 crore and have potential to generate 51,520 employment opportunities after getting operational. An amount of Rs 205.24 crore has been released for scheme execution.

The industry bodies have also stressed for promoting large scale electronics manufacturing. The NDA government amended this scheme twice – in August 2015 and in January 2017, and mainly provided a Capex subsidy of 20-25%. It was closed on 31st December 2018 to receive new applications. In this scheme, 320 applications with proposed investment of Rs 89,194 crore are under consideration. Out of these 320 applications, 315 applications with proposed investment of Rs 86,904 crore and committed incentives of Rs 9,566 crore have been approved. Incentives amounting to Rs 1917.09 crore have been disbursed.

The important point to be noted is that semiconductors form a major part of all electronic products, as a result of growth in the electronics manufacturing sector. This market in India has also witnessed proportionate growth over the last few years. As per the industry estimate, the semiconductor consumption in India was around Rs 1.1 lakh crore in 2020 which is being met through imports due to absence of commercial semiconductor fabs in India. The vision of AtmaNirbharta in electronics & semiconductors was given further momentum by the Union Cabinet chaired by the Hon‟ble Prime Minister approving the Semicon India program with a total outlay of Rs. 76,000 crores for the development of semiconductor and display manufacturing ecosystem in our country. According to minister of electronics and IT for State Rajeev Chandrashekar, India is now looking forward to achieving $56 billion in semiconductors by 2026 and $110 billion by 2030.

The total outlay of India’s semiconductor program has helped the country to witness US based global semiconductor company Micron’s new assembly and test facility in Gujarat, India at an investment of $2.75 billion out of which the company will receive 50 percent fiscal support for the total project cost from the Indian central government and incentives representing 20 percent of the total project cost from the state of Gujarat. Micron’s new facility will enable assembly and test manufacturing for both DRAM and NAND products and address demand from domestic and international markets.

Most importantly, India also witnessed the first semiconductor fabrication unit, a joint collaboration between Tata Electronics and Taiwan’s Powerchip Semiconductor Manufacturing Corp. (PSMC) with an investment of Rs 91,000 Crore. Apart from the fab approval, the cabinet also approved Tata Semiconductor Assembly and Test Pvt. Ltd’s ATMP unit in Assam with an investment of Rs 27,000 crore. Interestingly, Japan’s Renesas Electronics and India’s CG Power have also formed a joint venture to set-up another ATMP unit in Sanand region of Gujarat with an investment of Rs 75,000 crore. Interestingly, home-grown companies such as Sahasra group, Suchi Semicon, and HCL and in association with Foxconn have announced semiconductor OSAT units.

Global Strategies That Will Spurr India’s Growth in Electronics Value Chain

With the onset of COVID-19, anti-China sentiments started growing in India, US, Europe, and in several nations. In fact, the global companies such as Foxconn, Intel, Samsung, and others started finding alternatives other than China to set-up their production units. Apart from Vietnam and Philippines, India is the most preferred destination among the global companies.

Geopolitically speaking, ChinaPlus One Strategy is already helping India to grow its ESDM sector in various ways and the alliance with the USA will give India further impetus to boost its semiconductor industry both in terms of investment and revenues. The major problem is China is still leading the component industry and without that you can grow your industry. Therefore, both India and the US must find solutions to grow its component sector. Global investments have already happened in India and experts assure the close association with the US will make India a major player in the ESDM sector internationally.

As no one would like to put eggs in one basket. India has an added advantage in terms of design experts as leading semiconductor companies have design houses here and It's the manufacturing and IP where we catch up and we believe India is at the right place at the right time. Semi content within categories is increasing, while the electronic devices growth will continue too. Promoting product design, including both hardware and software can be a first step in making India a hub for the electronics system design and manufacturing sector. India semiconductor market consumption is all set to reach $64Bn by 2026 with a CAGR of 16 percent.

According to Mr. Rajoo Goel, India now stands out as a bright spot and beacon of hope. With our focus on the ESDM sector, India has been pulling out all stops for enabling the electronics eco-system and establishing itself as a serious player in the global industry. While our economy and markets are growing, demand growth outpaced supply and we remained dependent on growing imports. Concerted efforts in the last few years have salvaged the situation somewhat. However, much more needs to be done to create a sustainable ecosystem especially with respect to value addition and manufacturing of components.

"In this situation the India Taiwan partnership has great potential, particularly because we are aligned by our values of being trusted Partners and more importantly, our strengths and weaknesses complement each other. This presents a great opportunity for success through collaboration. Taiwan is looking to strengthen its partnerships in all domains with India, especially in the electronics and ICT domain. The gravitas with respect to India is growing with our steadily growing economy from 5th position currently to the expected 3rd rank by the end of this decade. All our trusted Partners and most of the world are looking towards the economic success of India with the conviction that India would be a stabilizing factor in the current fractured world and be a strong player in the global value chain,” added Mr. Goel.

Of late, various reforms and policy measures have been announced with an aim of escalating the share of manufacturing in gross value added (GVA) to 25 percent. In the financial year of 2019-20, the manufacturing cluster offered 17.1 percent of GVA and exports accounted for 20.7 percent of the overall manufacturing yield. The point to be noted is that none of the computer chips are completely manufactured in India yet and although US semiconductor firms have shown a lot of optimism to India there is still a discrepancy between what has been committed in eloquence and what has been assured in a signed document.

India’s Electronics Manufacturing Boom: From Import to Export

According to research body IBEF, overall, electronics manufacturing saw exponential growth to reach US$ 67.3 billion in 2020-21 from US$ 37.1 billion in 2015-16. However, the COVID-19 pandemic caused serious disruptions across the globe, but the industry has shown strong signs of recovery. India has been one of the pioneers of the Local Goes Global movement. The country is focusing on developing its share in the global value chain, establishing export hubs in different states, constructing a high-quality and seamless supply chain, and increasing its overall market share in the electronics export market. The Digital India Program has led to a paradigm transition towards digitization and e-governance in India. India's market share in the global electronics manufacturing industry increased to 3.6 percent in 2020 from 1.3 percent in 2012.

A US$ 1 trillion digital economy target is projected to boost demand for electronics, which may stand at around US$ 180 billion by 2025-26. If India can accomplish the manufacturing goal of US$ 300 billion for electronics, the local market requirement may be fully met by such manufacturing. The US$ 300 billion target also requires US$ 120 billions of exports in the global market.

Speaking about the growth of India’s EMS sector, Vinod Sharma, managing director, Deki Electronics, said, “India’s electronics manufacturing ecosystem is certainly growing very rapidly, but most importantly, the industry today believes that it has the potential to grow globally. India is now becoming a favored destination for electronics manufacturing. For instance, the PLIs for IT hardware, mobile phones, LED’s, and consumer electronics have mostly sparked the assembly department. It incentivizes locally made components, but in the last ten years, we have become a huge assembler and exporter at the same time. We are expecting that there will be some sort of incentives given by the government in component manufacturing. Although PLI is the most game-changing policy of all, it should reach the smaller companies and target the component sector. It mostly attracted the larger companies because the investment ratios are very high.”

India is one of the largest mobile handset manufacturing countries globally and the second-largest smartphone market in the world. The Ministry of Electronics and Information Technology (MeitY) unveiled the Phased Manufacturing Programme (PMP) for cellular handsets and other sub-assemblies with an aim to scale up domestic value addition. Manufacturing of mobile phones rose to 290 million units in 2020-21 from 60 million units in 2014-15. Mobile phone exports from India will grow more than fivefold to USD 50-60 billion in the coming time from about USD 11 billion last year, Union IT and Communications Minister Ashwini Vaishnaw said. He said that 10 years ago India imported 98 per cent of mobile phones and at present 99 per cent of the devices are made in India. Around 10 lakh people work in electronics manufacturing. In the coming days, 25 lakh people will work in electronics manufacturing. The minister also added that India will become the third largest economy by 2027 while it was ranked 11th in 2014.

Now, when it comes to the Information and Communication Technology (ICT) Hardware, the first use of electronics was in the communication and computing domain. In 2020, India witnessed a surge in ICT hardware demand due to COVID-19-led disruptions. Due to the remote working trend, households and individual customers purchased tablets and computers. Enterprises have heavily spent on their data center infrastructure (to ensure steady demand amid work-from-home and online dealings), and telecommunication service providers have been modernizing their infrastructure to cater to surging broadband demand.

Ten out of the 40 companies that applied for the Centre's revised production-linked incentive scheme for IT hardware have started production from 1 July 2023, while 25 plan to begin manufacturing by 1 April 2024, according to MeitY. The government expects an incremental investment of Rs 5,010 crore from the 40 applicants, including global IT hardware companies such as Dell and HP that are participating directly under the revised production-linked incentive scheme. Other major players such as HPE, Lenovo, Acer, ASUS, Thomson were participating through electronics manufacturing services providers or contract manufacturers including Flextronics and Rising Stars, a unit of Foxconn Technology Group in India. Officials added that Indian companies such as Padget, a subsidiary of Dixon Technologies, VVDN, Netweb, Syrma, Optiemus Technologies, Sahasra, Neolync, Panache, Sojo, a unit of Lava mobiles, and Kaynes have also participated in the scheme which will get impetus from the strong IT services industry which was driving the demand within the country.

Consumer electronics is another key domain whose manufacturing and demand has escalated tremendously in the country over the years. According to the Federation of Indian Chambers of Commerce & Industry (FICCI), India's television production was US$ 4.24 billion in 2020-21 and is anticipated to reach US$ 10.22 billion by 2025-26, expanding at a Compounded Annual Growth Rate (CAGR) of 20%. The kind of television sets available in the market includes a wide variety of LCDs, plasma, LEDs and so on, offering high resolution and sharp picture quality. Additionally, a decreasing trend in the pricing of LED and LCD televisions is fuelling the penetration of such televisions in the market. A few initiatives taken by the government include increasing the basic customs duty on multiple consumer electronics goods in order to push companies into replacing imported goods. Furthermore, the government has permitted 100% Foreign Direct Investment (FDI) in the consumer electronics manufacturing segment through the direct route and offered capital expenditure subsidy under the Modified Special Incentive Package Scheme (M-SIPS).

The ELCINA CTF report also highlighted that the industry’s ecosystem has evolved to keep pace with the changing demand patterns. The supply chains are now far more complex, diverse, and optimized to meet the new industry structure. Currently, a significant share of Indian demand is met by imports. But the Indian electronics industry is being ushered into an era wherein the manufacture of several components will be indigenized through regulatory support and incentivized production from the government of India. There have been several policies such as Make in India, National Policy of Electronics 2019, Production Linked Incentives (PLI) & Phased Manufacturing Program (PMP) etc. which are primarily to promote domestic manufacturing, lowering import dependence, and expanding exports.

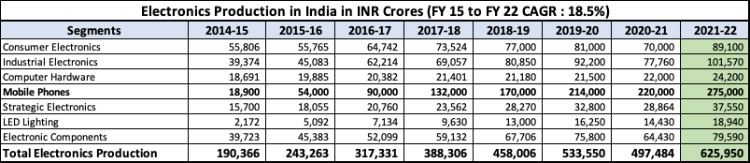

The electronics industry in India has been one of the fastest growing sectors. It has grown at a healthy pace of 15% over the last 7 years, despite Covid as shown in the Chart below. The Indian Electronics manufacturing has reached Rs 625,950 Crores in 2021-225 comprises of Mobile Phones (44%), Industrial Electronics (16%), Consumer Electronics (14%), Electronic components (13%), Strategic Electronics (6%), Computer Hardware (4%) and LEDs (3%).

Highlighting further on India’s potential to grow the industry, Amrit Manwani, managing director Sahasra Group, said, “The industry has seen sea change towards policy for this sector. In the last tens years, the electronics industry has seen a proper direction that has helped to expand its presence in the global market. All the three PLIs which have been announced in the last three years including the SPECS scheme have boosted investments in the sector. But as far as PLI for IT hardware 2.0 is concerned, this should actually stimulate the manufacturing of IT hardware products in India, which has witnessed a very nominal growth in the last seven decades. In the coming five to six years, this scheme will pose a significant growth in electronics manufacturing. It will not only make us self-reliant, but will also address various security concerns through the import of the IT hardware products.”

Source: ELCINA CTF 2.0

Growth of India’s Electronic Components Market-Overview

Although India has set to achieve a target of $300 billions of electronics by the end 2025, industry leaders feel that the country’s component manufacturing is still in its nascent stage. According to Viond Sharma, managing director of Deki Electronics, in the current product mix, out of the 100 billion dollars, we are actually manufacturing 52.7 percent of the electronics components, according to last year's data. Around 150 billion dollars of components will be required to reach the target.

The global market for electronic components is expected to reach USD 2,628 billion in 2022, of which the Asia Pacific region is going to capture a dominant share. Following this global trend, the Indian electronic components market is also poised to grow significantly. This growth will be driven by rising local demand and growing disposable incomes. Apart from this, the adoption of high-end technology devices, technology-driven transformation such as the roll-out of 5G/4G/LTE networks and the Internet of Things (IoT), policy and incentive boosts from the government like ‘Digital India’ and ‘Smart Cities’, wider broadband connectivity, e-governance programmes, etc, are all driving the accelerated adoption of electronic products.

The growth of the electronic products industry has started driving the expansion of the electronic components industry as well. According to ELCINA, the market size of the Indian Electronic Components Market in India [(Domestic Production – Exports) +Imports] increased from USD 11 billion in FY 2009-10 to USD 29.9 billion in FY 2021-22 (excluding the Imported PCB-Assemblies), with a year-on-year growth rate of around 8.7 percent. The Electronic Components Market has largely grown driven by a huge increase in Mobile Phones manufacturing in India in the last 2 years. The Electronic Components Market in India including Imported PCB-Assemblies is estimated to be around USD 39.2 billion.

Mobile Phones, Consumer Electronics and Industrial Electronics account for the major demand (85%) for electronic components in India. This is followed by Computer Hardware, strategic electronics and lighting industry contributing to the balance of the market. The Indian Electronic Components Market seems to be largely dependent on imports which accounts for over 68 percent of the Indian Market requirement. Nearly 37% of the local production of Electronic Components is exported. Industries like Mobile Phones, Industrial Electronics (due to the advent of EVs) and Strategic Electronics are expected to witness substantial growth in the near future. The Indian Electronic Components Market (Excluding Imported PCB-Assemblies) was estimated to be around USD 27.3 billion in FY 2021-22 as shown below in Chart below.

Some Additional Developments: In a Nutshell

- In the interim budget 2023-24, apart from the incentive scheme of Rs 76,000 crore unleashed in December 2021, the finance minister allocated Rs 3,000 crore in the budget session of FY 2023-24 and this year the amount has been increased to Rs 6,903 Crore.

- In terms of mobile manufacturing, the PLI scheme has been increased to Rs Rs 6,125 crore, up from Rs 4,489 crore in the last year.

- Production-linked scheme (PLI) for large-scale electronics manufacturing (including mobiles) has seen investments worth Rs. 6,887 crore (US$ 833 million) (till June 2023), already surpassing the target for FY24 which was Rs. 5,488 crore (US$ 664.4 million).

- India has overtaken China as the second-largest manufacturer of mobile devices in the world, according to a report released by the international research firm Counterpoint in August. The ‘Make in India’ initiative's mobile phone shipments from India exceeded 2 billion cumulative units and an annual growth rate of 23% was recorded.

- The Ministry of Electronics and IT (MeitY) announced the exchange of signing of a Memorandum of Understanding (MoU) between the Centre for Nano Science and Engineering (CeNSE) at the Indian Institute of Science (IISc), Bengaluru and Lam Research India at the SemiconIndia in Gandhinagar.

- In November 2023, Mr. Ashwini Vaishnaw, Union Minister of Communications & IT said that 99% of mobiles used in India are made in India.

- In FY23, the exports of electronic goods were recorded at US$ 23.57 billion as compared to US$ 15.66 billion during FY22, registering a growth of 50.52%.

- During April 2022-February 2023, the imports of electronics goods stood at US$ 70.07 billion, whereas exports stood at US$ 20.69 billion.

- A joint venture of Corning and Tamil Nadu state government agreed to invest Rs 1,000 crore underscoring the growing importance of the south Asian country as a manufacturing hub.