With the ever-increasing consumption of fossil fuels, the governments of various countries are taking steps towards the electrification of vehicles. Last year, the Government of the UK said that it would ban the sales of new cars and vans powered by diesel and petrol by 2030. Despite efforts being made for the decisive shift away from the internal combustion engine what could be the reason that we are not seeing many electric cars hitting the roads? Well, one of the major reasons is the hefty price of current batteries being used in EVs. Bloomberg New Energy Finance states that batteries add 30% to the total cost of the EV.

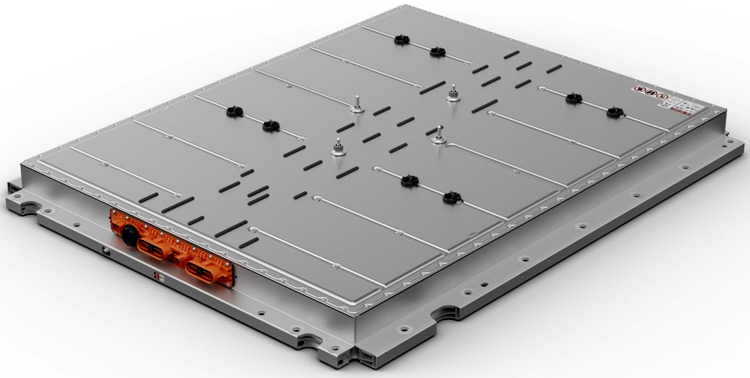

Electric Vehicles majorly use four types of batteries viz. Lithium-ion batteries, molten salt (Na-NiCl2 ), Nickel Metal Hydride (Ni-MH), and Lithium Sulfur (Li-S). However, lithium-ion batteries dominate the battery market because it has high energy density and increased power per mass, even though it has the possibility of having the same power capacity as the other batteries. These batteries control more than 90% of the global grid battery storage market. It is very much the winning clean technology. These are the only types of batteries that pack powerful energy storage in a compact and lightweight design.

ISRO, Exide Industries, EON Electric Ltd, HBL Power Systems, Amara Raja Batteries, etc. are the major Li-ion battery manufacturers in India that are working on making Li-ion batteries more efficient. Israeli company, StoreDot is aiming to deliver 100 miles of charge to a car battery in five minutes in 2025. Likewise, many other companies are working on improving the battery efficiency providing extreme fast-charging and delivering long miles of charge.

Despite major developments happening to lessen down the limitations of lithium-ion batteries, their supply chain is becoming constrained for miscellaneous reasons, one being high price. Moreover, commercial lithium-ion batteries rely extensively on cathodes that contain cobalt which is not only expensive but adds to the environmental hazards too. Companies around the globe are working towards developing new technologies and smart alternatives to Li-ion batteries.

US car giant, Tesla has made advancements in batteries and is placing a huge bet on rechargeable battery technology that doesn’t use cobalt. Last year, Tesla revealed that it was working with CATL on lithium iron phosphate LFP batteries that don't use cobalt and aim to achieve $100 per kWh (wholesale). Sounds interesting, right?

James Frith, head of energy storage at Bloomberg New Energy Finance stated that LFP batteries were over $1,000 per kWh in 2010, $381 in 2015, and around $147 per kWh in 2020. The price has slashed even more. He estimated that LFP batteries will hit $100 per kWh by 2023 or 2024, and $61 by 2030.

A new study by CEEW Centre for Energy Finance states that electric vehicles will be a $206 billion opportunity for India by 2030 for which an annual battery capacity of 158 GWh is needed.

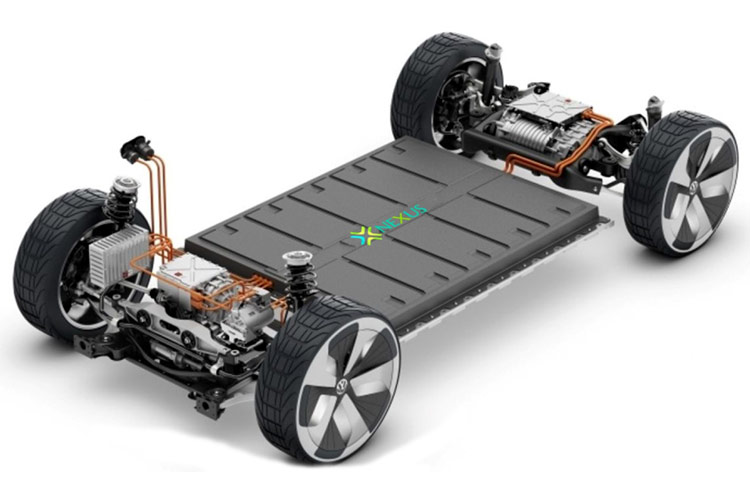

Nexus Power, a Bhubaneswar-based startup by twin sisters, Nishita and Nikita Baliarsingh was started with the aim to build biodegradable electric vehicle batteries from crop residue, with the main focus on batteries for electric two and three-wheelers. Nikita Baliarsingh, Co-Founder and COO of the company shared her views on the battery technology developments for electric vehicles and more.

Talking to her, we got to know more about the problems of using Li-ion batteries in EVs, other types of batteries being manufactured for EVs and how far would the shift from Li-ion batteries to other batteries prove beneficial. Here is what she said:

“Lithium-ion batteries are normally imported in India which makes the entire process of procurement and assembly quite expensive. This in turn increases the cost of the vehicle, because of which most of the average Indian households can't afford it. Another major concern is the threat that lithium throws at the environment. It is highly toxic and hazardous. The time these batteries take to attain a full charge is very long and it does not provide an adequate KM range as well. Overall, although Li-ion batteries were a revolution, so many concerns can be identified which need immediate attention for a progressive adaptation of electric vehicles in India.

As far as other types of batteries are concerned, alternate technologies in batteries are an upcoming trend but the numbers are still scarce. Graphene, silicon, lithium - polymer, etc. are some of the fresher known concepts in battery technology. Most of these batteries are still in the initial stage of development. Solid-state batteries are also in the pipeline. Apart from these, hydrogen fuel cells and metal-air batteries are undergoing R&D as well. There might be some interesting options in the future in terms of EV batteries for the Electric Vehicle manufacturers and OEMs. In the present scenario, the Li-ion battery is the only promising product as per its durability and efficiency.

The other battery technologies are not just more eco-friendly but quicker at charging and long-lasting as well. This will mean that the charging time of the electric vehicles will reduce whereas the KM range on a single charge will increase. The fresh concepts also boast a higher energy density. With all these parameters, most of the other battery manufacturers claim that their batteries are a cheaper offering than Li-ion batteries. Overall, the shift will reduce costs for the manufacturers of electric vehicles. At the same time, new concepts will be more efficient, durable, and compatible with the changing trends. This will not only make the vehicle more sellable but also more user-friendly for the consumers. The shift will mark a boom in the electric vehicle industry.”

Possible Alternatives of Lithium-ion Batteries for Electrical Vehicles

From shunning cobalt to working on the technology for lithium metal/anode-free batteries, all-polymer batteries, there are many technological advancements taking place to make EVs feasible, commercially viable owing to battery durability and price reduction along with less impact on the environment. Let's take a closer look at what's beyond Lithium-ion batteries for EVs.

1. Lithium-Sulfur Batteries

Li-sulfur batteries can overcome Li-Ion battery limitations in terms of cost, the abundance of material (sulfur) available with a reduced environmental footprint. These batteries have a much higher energy density in comparison to Li-ion batteries. Another great advantage of Li-S batteries is the affordability owing to sulfur being a more abundant material than cobalt. The Li-S battery system has a redox reaction-based storage mechanism, which delivers higher energy density because of the formation of Li2S when sulfur combines with lithium. Sulfur is sourced from industrial waste and cardanol is sourced from bio-renewable feed-stock that is easily available, non-toxic, and environmentally friendly.

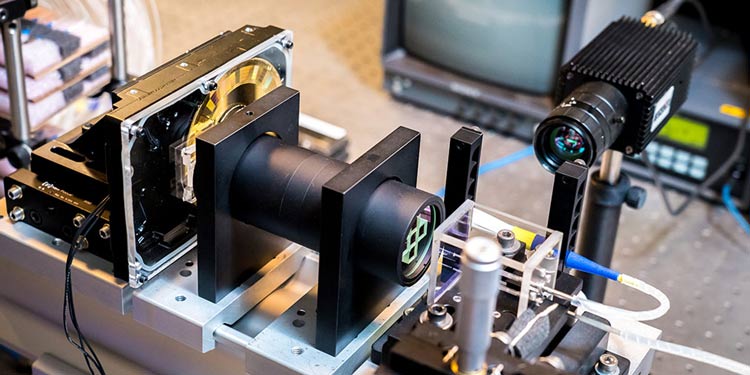

After five long years of extensive research by Shiv Nadar University’s Associate Professor in the Department of Chemistry, Dr. Bimlesh Lochab announced the development of a technology of Lithium-Sulfur (Li-S) batteries. It is said that the research will aid the production of cost-effective, compact, energy-efficient, safe, and environment-friendly Li-sulfur batteries, offering a viable alternative to Lithium-ion batteries used at present.

The Li-Sulfur battery technology by the university leverages principles of Green Chemistry, incorporating the usage of by-products from the petroleum industry (Sulfur), agro-waste elements, and copolymers such as cardanol (a by-product of cashew nut processing) and eugenol (clove oil) as cathodic materials. From gadgets to drones, electric vehicles (EV), and other products, the Li-S battery has the potential to aid multi-billion dollar industries.

Also, a few months back, researchers at Monash University in Australia developed a very high-performance and energy-efficient lithium-sulfur (Li-S) battery with a potential electric vehicle (EV) range of 1000 KM.

2. Zinc-ion Batteries

Recently, scientists from Zhejiang University, China, and the Chinese Academy of Sciences have developed a metallic tin coating for zinc anodes that increases the stability and lifetime of zinc-ion batteries. The new batteries that will be developed will have a water-based electrolyte which might offer a safer, cheaper alternative to lithium-ion batteries.

According to Salient Energy, the zinc-ion battery is considered safer than its lithium-ion counterpart, because it uses water as the electrolyte. The zinc-ion batteries do not require formation cycling at the end of life meaning the production of zinc-ion batteries can be rapidly and inexpensively scaled-up.

3. Aluminium-air Batteries

Last year, Indian Oil Corporation announced that it will launch first-of-its-kind aluminium-air batteries that are potentially a more cost-effective alternative to lithium-ion batteries for use in electric vehicles (EV) and stationary applications. IOC bought a minority stake in Israel-based startup, Phinergy which specializes in aluminium-air and zinc-air battery systems. The aluminium-air batteries can expectedly reduce the cost. Moreover, Al-air batteries are lightweight and need not be electrically charged. Besides, there is no mechanical electric charging or replacement required for Aluminium batteries

4. Graphene Supercapacitors

Supercapacitors can provide ample energy when required. Combining battery and supercapacitor technologies into a new hybrid battery could fulfill short and long-term power needs, reducing stress on the battery at peak loads, leading to longer service life thereby, helping in developing smaller and lighter battery packs. Electric vehicles need an extra energy spurt for acceleration and supercapacitors can help does the needful. They hold a limited amount of charge and can deliver it fast. This makes them the perfect complement to mass-storage batteries.

Moreover, supercapacitors offer a high power output in a short time, meaning a faster acceleration rate of the car and a charging time of just a few minutes, compared to several hours for a standard electric car battery.

Hydrogen fuel cells, Redox flow batteries, Aluminum-graphite batteries, Bioelectrochemical batteries, and Thin-film batteries are other smart alternatives of lithium-ion batteries being worked upon. Powered roads and solar panels too can be mentioned in the list of smart alternatives to lithium-ion batteries.

Looking into the nanoparticles side, graphite is used in lithium-ion batteries but it is found that silicon stores 10 times more energy than graphite. There were many successful attempts made to replace graphite with silicon in lithium-ion batteries until scientists at Sila Nanotechnologies solved the issue with a nanocomposite of silicon and other materials. There are other problems like (environmental consequences of using lithium, its high cost, and less availability) that some nanomaterials scientists are working on. This is what they call, “Beyond lithium-ion” batteries and various ways are being explored to replace lithium with materials like sodium, potassium, magnesium, and aluminum.