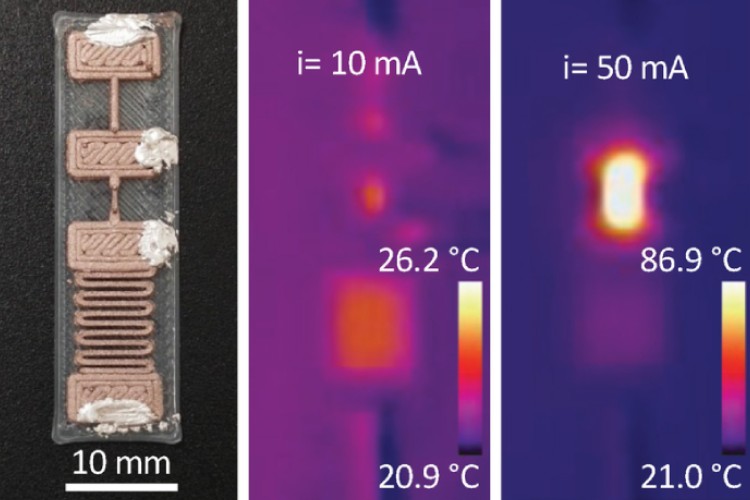

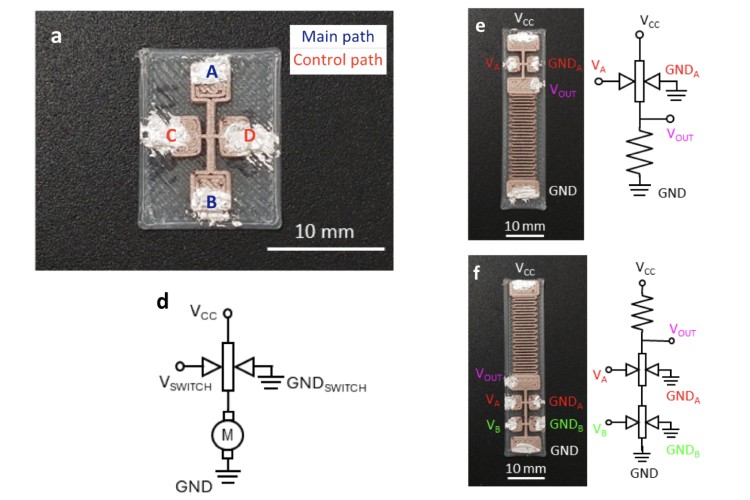

Researchers at MIT have made a significant development in electronics with the development of a fully 3D-printed, presenting semiconductor-free active electronic devices. This new breakthrough involves the creation of 3D-printed, semiconductor-free logic gates and resettable fuses, both fabricated entirely through an accessible, additive manufacturing process. These devices, constructed from a copper-doped polymer, offer new potential for electronics production, potentially shifting fabrication away from specialised, high-tech facilities. The research paper outlines how these devices control electrical signals without the need for traditional semiconductors. The technology leverages 3D printing to create conductive regions that enable resistance regulation via voltage control, mimicking the switching behaviour of semiconductor transistors used in modern electronic devices.

Luis Fernando Velásquez-García, the lead researcher, emphasises that while the performance of these 3D-printed devices does not yet match that of silicon-based electronics, their creation demonstrates a promising path toward decentralised electronic fabrication. This approach could reduce reliance on complex semiconductor supply chains, as exposed during the COVID-19 pandemic. By using low-cost materials and standard 3D printing hardware, MIT's innovation aims to make electronics production accessible to a broader range of users, including small businesses, research labs, and even individual hobbyists. This marks an exciting step toward the future of electronics manufacturing, one where fully functional devices could be printed on demand without the need for expensive and specialised equipment.

Looking forward, the MIT team envisions advancing this technology to create more complex systems, possibly even including motors and other electromechanical components. Their work opens the door for further exploration into how 3D printing can revolutionise the design and production of electronic systems.