PCBs are the backbone of every electronic circuitry. PCBs make them compact, easy to build and easy to troubleshoot. Every maker starts with breadboards for initial developments and moves forward with PCBs for faster and more reliable product development. In the past, the best way to make the prototype PCBs was to make them at home. One major reason for relying on a homemade PCB was that the PCB prototyping was pretty expensive in the past. Now with the cost for prototype PCBs as low as 2$, the PCB complexity has increased and we transitioned to tiny SMD components, most of us don’t even bother to fabricate homemade PCBs. But even though they have become cheap, there is another crucial thing that makes homemade PCBs still relevant, and that is time. It is not practical to go for professional PCB prototyping when there are rapid changes or time-sensitive revisions are needed.

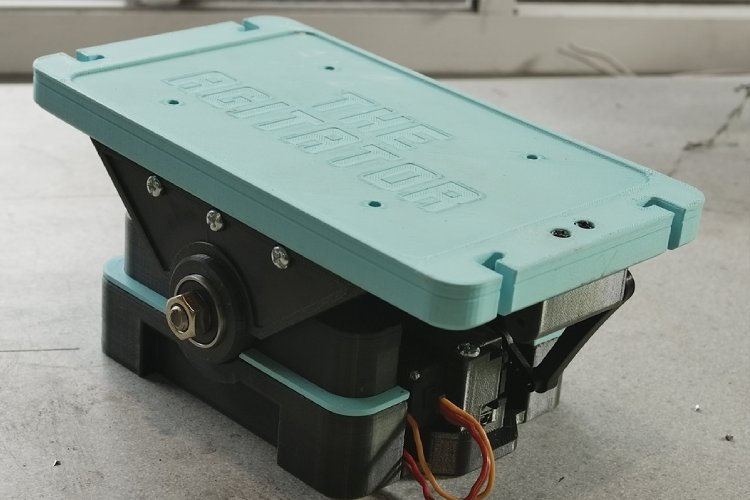

Now that we have seen why home PCBs are still relevant, let's look at how they are made. The first thing is to transfer the artwork to the PCB clad using methods such as toner transfer or photoresist methods. Then the next step is to chemically etch the unwanted copper from the PCB surface. This is the most infuriating step because we must agitate the etching solution continuously to get a faster and more appropriate result. That’s where Chris Borge’s automatic PCB agitator comes into play. This automatic agitator uses a servo motor to move a platform, in which the container with the etching solution and the PCB is secured, in a continuous pattern resulting in a faster etching process. Apart from the bearings and fasteners, almost all of the mechanical parts for the automatic agitator are 3D-printed parts. Inside the agitator, there Borge used an Arduino to control a servo motor, which creates a reciprocating motion and moves the platform accordingly. If you want to know more, check Borge’s YouTube video for more information about the project. He is planning to release all the design files for everyone who wants to make their own automatic agitator.