Companies can now move to hyperscale data centers and use their cloud service to lessen the total energy utilization

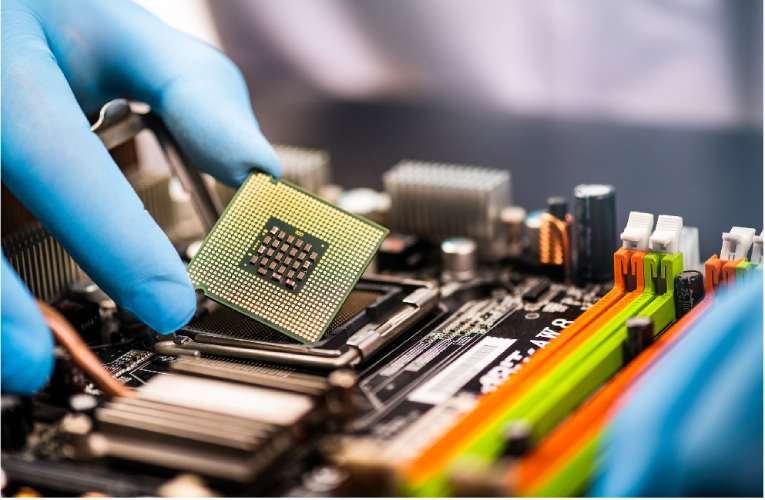

There is a massive carbon footprint when semiconductors are being manufactured, especially from the mining procedure utilized to refine and extract the component materials to the chip fabrication steps. Sustainability does not mean that it can reduce carbon footprint largely, but it is very imperative for semiconductor firms to perk-up their manufacturing processes and craft innovative services and products.

Then, the point is how the semiconductor firms can bring sustainability in their manufacturing processes. For instance, data mastery is very key to a sustainable future and at the same time offers competitive advantage. In order to spearhead the strategic growth insights, the analytics of semiconductor manufacturing adapts yield enhancement use cases, data engineering requirements, and data strategy goals. According to the experts, analytics during manufacturing can unveil substantial value like decreasing the downtime of the machine by upto 50 percent and enhancing the manufacturing yield by upto 5-15 percent by introducing deep and machine learning.

Then, in another way the companies can move to hyperscale data centers and use their cloud service to lessen the total energy utilization. They can also opt for green energy resources by moving to those areas where local renewables are abundant and the workloads should be at a time when the renewables are available in plenty. In order to meet the same, businesses must commence by developing a baseline of current data center energy consumption sustainability goals, and computing requirements. Most importantly, companies must quantify the greenness of prospective cloud solution options that are dependent on a range of information such as energy sources, cloud service provider’s carbon emission goals, transformation to clean energy, and locations.

Supply chain management is another important area for sustainable semiconductor manufacturing. Alliances and coordination all through the supply chain is quite complex which is why SEMI’s Sustainability Advisory Council is looking to standardize sustainability reporting processes and share correct data all through the supply chain. According to an exclusive report of EETimes, companies also need to pursue responsible sourcing with their suppliers. For example, manufacturers such as ASML are joining the Responsible Business Alliance, the world’s largest industry coalition dedicated to corporate social responsibility in global electronics supply chains.