As the automobiles are transitioning from mechanical to electrical, the use of ECUs (electronic control units) has increased to a higher percentage. The ECUs in the electric vehicles act as the brainpower of the vehicle and are responsible for all the most important features such as safety with the help of ADAS, precise engine control, connectivity, efficiency, and comfort. So the need for testing each ECU used is really important and it requires a more advanced process to do so.

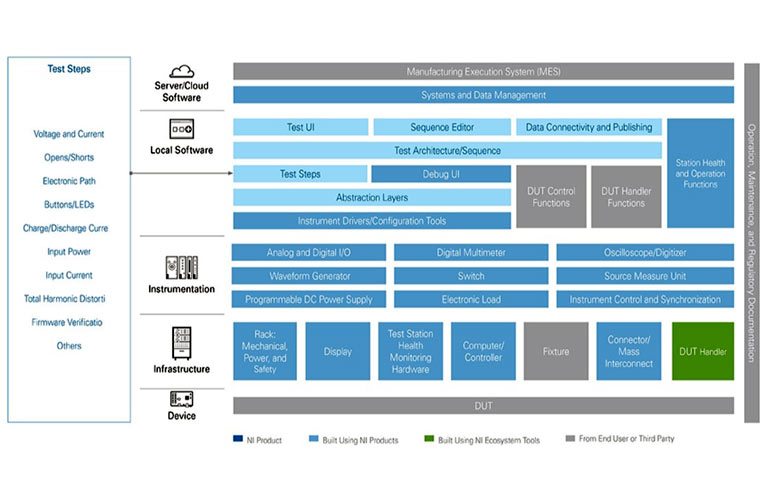

To address the above issue, NI has announced its ECU Test System Offering. The ECU Test System (ECUTS) is a combined solution of standardization with the flexibility to drive efficiency in tester development, maintenance, and test time. The tester has integrated the first level of common components into a standardized test architecture to save customers time in the development process and to simplify tester maintenance. The modular PXI design makes testing more flexible and one can scale across a range of body, chassis, and power train ECUs along and the high-performance hardware can help reduce test time.

The ECUTS can accelerate development, standardize on global architecture, reduce test cycle time, reduce floor space, and reduce risk. Lowering the cost of tests for ECUs frees up both monetary and cognitive capital, so test engineers can solve today's problems and innovate on the test challenges of tomorrow.