The durability and dependability of an electronic circuit are highly dependent on how well it is designed considering all odds, which could practically occur when the product is actually in use. This is particularly true for all power supply units like AC-DC Converters, or SMPS Circuits because they are connected directly to the AC mains and a varying load which makes them susceptible to overvoltages, voltage spikes, overloading, etc. This is why designers include many types of Protection circuits in their design, we have already covered a lot of popular protection circuits namely

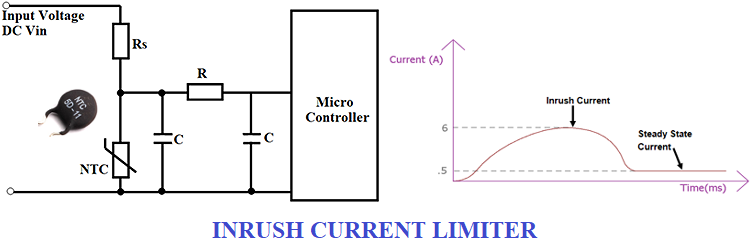

We previously discussed Inrush current, in this article we will discuss how to design an inrush current limiter circuits, to protect your Power supply designs from inrush currents. We will first understand what inrush current is and the reason why it is generated. Then we will discuss the different types of circuit design that can be used to protect inrush current and finally conclude with some tips to protect your device against inrush current. So, let’s get started.

What is Inrush Current?

As the name suggests the term “inrush current” indicates that when a device is turned on during the initial stage a huge amount of current rushes into the circuit. By definition, it can be defined as the maximum instantaneous input current drawn by an electrical device when it is turned on. This behavior can be well observed in AC inductive loads like Transformers and Motors, where the inrush current value will normally be twenty or thirty times more than the nominal values. Even though the value of inrush current is very high it occurs only for a few milliseconds or microseconds hence cannot be noticed without a meter. Inrush current can also be called as Input surge current or Switch-on surge current based on convenience. Since this phenomenon is more with AC loads, AC Inrush current limiter is more used than its DC counterpart.

Each and every circuit draws current from a source depending on the state of the circuit. Let’s assume a circuit that has three states, that is idle state, normal working state, and maximum working state. In idle state consider, the circuit draws 1mA of current, in a normal working state the circuit draws 500mA of current and in the maximum working state it can draw 1000mA or 1A of current. Therefore, if the circuit mostly works in a normal state, we can say that 500mA is the steady-state current for the circuit, whereas 1A is the peak current drawn by the circuit.

This is fairly true, easy to work with and simple math. But, as told earlier there is another state exists where the current drawn by the circuit can be 20 or even 40 times larger than the steady-state current. It is the initial state or power on stage of the circuit. Now, why this high current is suddenly drawn by the circuit as it is rated for low current application? Such as the previous example, 1mA to the 1000mA.

What causes Inrush Current in a device?

To answer the questions we have to get into the magnetics of inductor and motor coils, but to start let’s consider that, it’s like moving a huge cupboard or pulling a car, initially, we need high energy, but as things start moving, it became easier. Exactly the same thing happens inside a circuit. Almost every circuit, especially power supplies, uses large value capacitors and inductors, chokes, and Transformers (a huge inductor) all of which draw a huge initial current to develop the magnetic or electric field required for their operation. Thus the input of the circuit suddenly provides a low resistance (impedance) path which allows a large value of current to flow into the circuit.

Capacitors and inductors behave differently when they are in a fully charged condition or discharge condition. For example, a capacitor when it is in a fully discharged condition acts as a short circuit due to the low impedance, whereas a fully charged capacitor smoothens out the dc if connected as a filter capacitor. However, it is a very small span of time; in few milliseconds the capacitor gets charged. You can also read about the ESR and ESL values of a capacitor to better understand how it works in a circuit.

On the other side, Transformers, motors, and inductors (all coil related stuff) generates back emf during startup, also requires very high current during the charging state. Normally, few current cycles are required to stabilize the input current to a steady-state. You can also read about DCR value in the inductor to better understand how inductors work in a circuit.

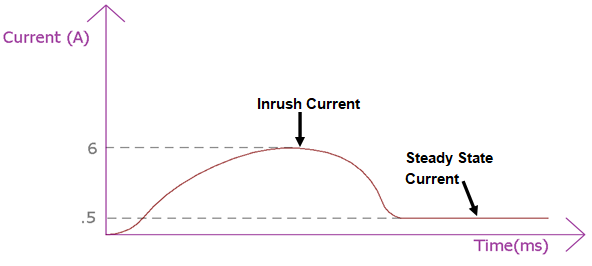

In the above image, a current vs. time graph is shown. The time shown in milliseconds but that can be in microseconds too. However, during the startup, the current start to increase and the maximum peak current is 6A. It is the inrush current that exists for a very short time span. But after the inrush current, the current flow gets stable at a value of .5A or in 500mA. This is the steady-state current of the circuit.

Therefore, when the input voltage is applied to the power supply or in a circuit that has very high capacitance or inductance or both, inrush current occurs. This initial current as shown in the inrush current graph gets very high to cause the input switch melting or blown-up.

Inrush Current Protection Circuits – Types

There are many methods to protect your device from inrush current and different components are available to protect the circuit from inrush current. Here is the list of effective methods to overcome inrush current-

Resistor limit method

There are two ways to design inrush current limiter using the resistor limit method. The first one is to add a series resistor to reduce the current flow in the circuit line and the other one is to use line filter impedance in AC supply input.

But this method is not an efficient way to add across a high output current circuit. The reason is obvious because it includes resistance. The inrush current resistor gets heated up during normal operation and reduces efficiency. The resistor wattage depends on the application requirement, typically ranges between 1W to 4W.

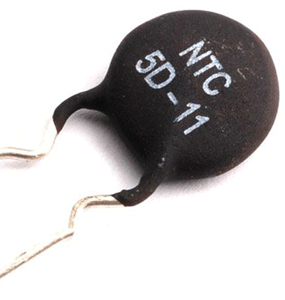

Thermistor or NTC based current limiter

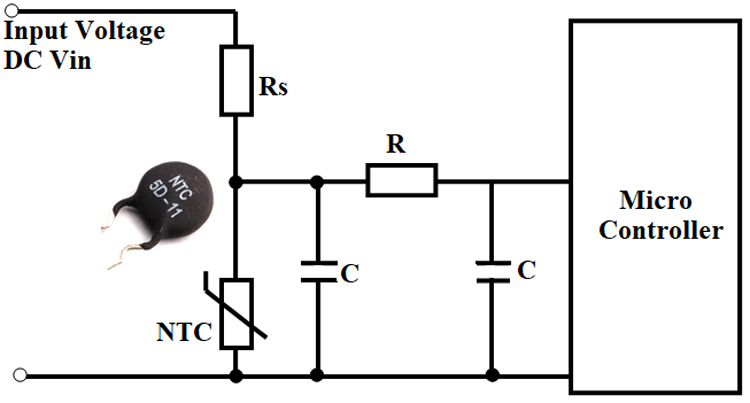

The Thermistor is a temperature coupled resistor that changes resistance depending on the temperature. In an NTC inrush, current limiter circuit is similar to resistor limiting method, Thermistor or NTC (Negative temperature coefficient) is also used in series with the input.

Thermistors have characteristics of changed resistance value at different temperatures, specifically, at low-temperature Thermistor behaves like a high-value resistor, whereas at high temperatures, it provides low-value resistance. This property is used for the Inrush current limiting application.

During the initial startup of the circuit, the NTC provides high-value resistance which decreases the inrush current flow. But during the circuit goes into the steady-state condition, the temperature of the NTC starts increasing which further resulted in low resistance. NTC is a very effective method of controlling inrush current.

Soft Start or Delay circuit

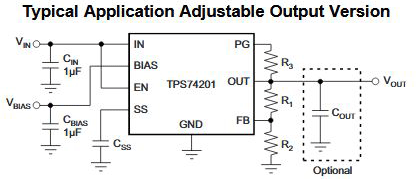

Different type of voltage regulator DC/DC converters uses the soft start or delay circuit to reduce the inrush current effect. Such type of functionality enables us to change the output rise time which effectively reduces the output current when connected to a high-value capacitive load.

For example, 1.5A Ultra-LDO TPS742 from Texas Instruments offers programmable soft-start pin where the user can configure Linear Start Up using a simple external capacitor. In the below circuit diagram, an example circuit of TPS742 is shown where the soft-start time is configurable using the SS pin by using the CSS capacitor.

Where and why we need to consider Inrush Current Protection Circuit?

As discussed before, the circuit where high-value capacitance or inductance exists, an inrush current protection circuit is required. The inrush current circuit stabilizes the high current requirement in the initial starting stage of the circuit. An inrush current limiter circuit limits the input current and keeps the source and the host device safer. Because a high inrush current increases the failure chances of the circuit and that needs to be rejected. Inrush current is harmful because of the following reasons-

- High inrush current affects the source power supply.

- Often high inrush current drops the source voltage and results in a brownout reset for microcontroller-based circuitry.

- In few cases the amount of current supplied to the circuit gets beyond the acceptable maximum voltage of the load circuit, causing permanent damage to the load.

- In high voltage AC motors, the high inrush current causes the power switch to trip or sometimes burned out.

- The PCB board traces are made to carry a specific value of current. The high current could potentially weaken the PCB board traces.

Therefore, to minimize the effect of inrush current, it is important to provide an inrush current limiter circuit where the input capacitance is very high or has a large inductance.

How to measure Inrush Current:

The main challenge of measuring inrush current is the fast time span. Inrush current occurs for a few milliseconds (or even microseconds) depending on the load capacitance. The value of the time span generally differs from 20-100 milliseconds.

One easiest way is to use the dedicated clamp meter which has the option to measure the inrush current. The meter gets triggered by the high current and takes multiple samples to get the maximum inrush current.

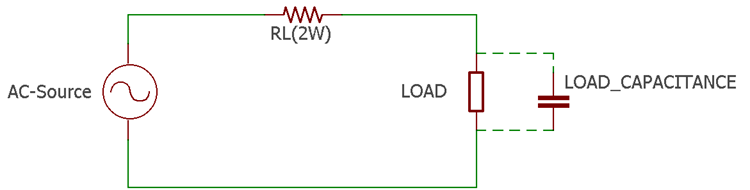

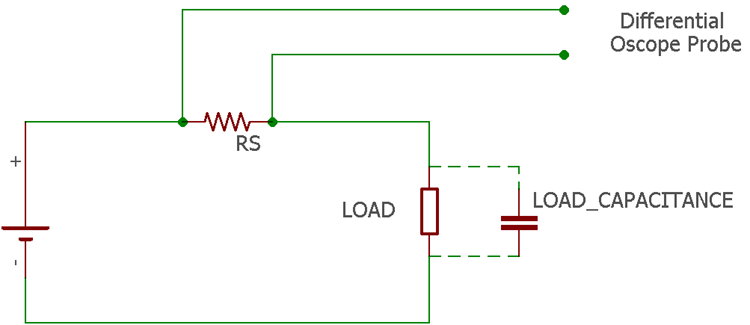

Another method is to use a high-frequency oscilloscope but this process is a bit tricky. One needs to use a very low-value shunt resistor and requires two channels to connect across the shunt resistor. By using the different functions of these two probes one can get the maximum peak current. One needs to be careful while connecting the GND probe, the wrong connection across the resistor could lead to a short circuit. The GND needs to be connected across the circuit GND. The below image is the representation of the above-mentioned technique.

Factors to consider while designing an Inrush Current Protection Circuit:

Some different factors and specifications are needed to be taken into the account before choosing the inrush current limiting method. Here is a list of few essential parameters –

1. The capacitance value of the load

The capacitance of the load is essential parameters to select the specification of inrush current limiting circuit. High capacitance requires a high transient current during startup. For such a case an effective soft start circuit is required.

2. Steady-state current rating

Steady-state current is a huge factor for the efficiency of the current limiter. For example, the high steady-state current could lead to increased temperature and poor efficiency if the resistor limit method is used. NTC based current limiting circuit can be a choice.

3. Switching time

How fast the load gets on or off during a given time frame is another parameter to choose the inrush current limiting method. For example, if the switching on/off time is very fast then the NTC could not protect the circuit from inrush current. Because, after a first cycle reset, the NTC does not get cooled down if the load circuit is turned off and on in a very short time span. therefore the initial start resistance couldn’t be increased and the inrush current gets bypassed through the NTC.

4. Low voltage and Low current operation

In specific cases, during circuit design, if the power source and the load is existing inside the same circuit it is wiser to use voltage regulator or LDOs with soft start facility to reduce the inrush current. In such a case, the application is a low voltage low current application.