When it comes to electronic components or electronic devices, there are always certain types of standards that ensure the reliability and quality of the product. In the case of the PCB or Printed Circuit Boards, the IPC standards are used to ensure quality throughout the manufacturing process. In this article, we will look into the IPC standards for PCB its purpose and what we should consider from it as an engineer designing the PCB.

If you are an absolute beginner and are just getting started with PCB designing then, you can consider reading this basic of PCB article and then coming back to this one. You can also check out the various PCB projects that we have built along the way if you are more of a hardware person. That being said let's get back to our IPC standards for PCB design.

What is IPC Standard?

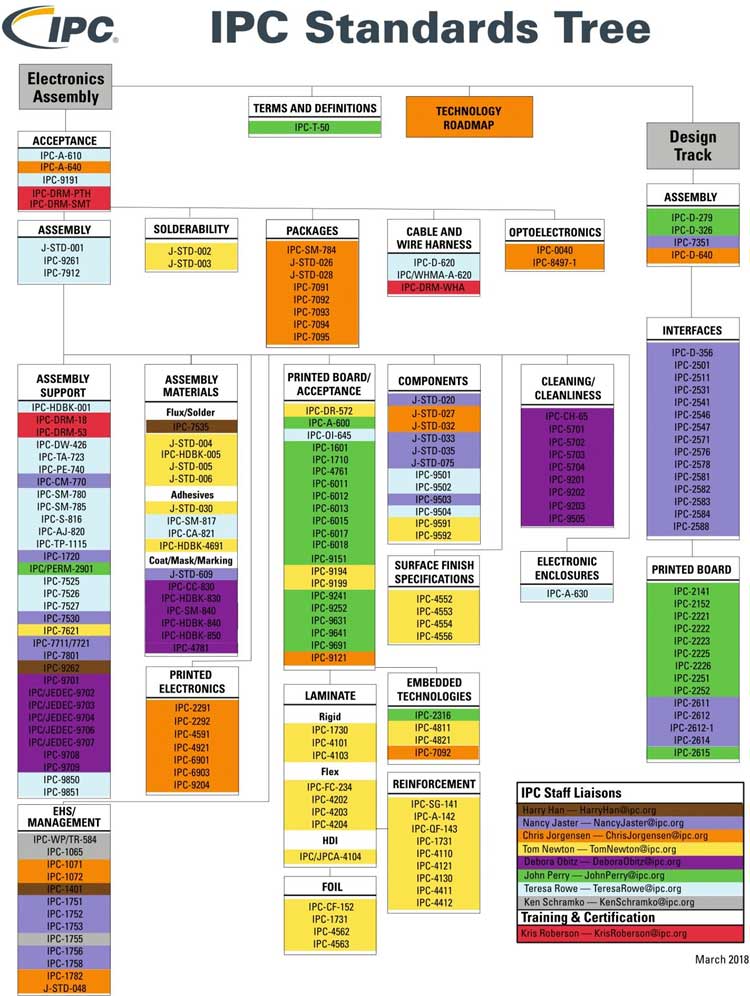

IPC-Association Connecting Electronics Industries is a global trade association that sets certain standards for the manufacture of PCBs and other types of electronics components. Apart from manufacturing, it also provides standards for the assembly, protection of electronic equipment, training, market research, and public policy advocacy.

The IPC has more than 4500 companies all over the world as its members, these members are from various aspects of the electronics industry like designers, board manufacturers, suppliers, assembling companies and equipment manufacturers.

History behind IPC

IPC is a member-driven organization that was formed by six printed circuit board manufacturers in the year 1957, in the name of “Institute for Printed circuit boards”. The organization was formed with the intention of removing the supply chain obstacles, creating industry standards and supporting the advancement of the industry.

Later the organization changed its name to the Institute for Interconnecting and Packaging Electronic Circuits, from the year 1999 they have adopted the name IPC with the tagline Association Connecting Electronics Industries. But, the full form for IPC stands for the Institute of Printed Circuit. The headquarters of IPC is located in Bannockburn lll, it also has offices in major countries like the United States, China, India, Sweden, and Russia.

Why is IPC standard Important?

The IPC standards make sure that the manufacturers build safe, reliable and high performing PCB boards by taking attention on the details of the manufacturing and dedication towards maintaining the quality throughout the manufacturing process.

These standards help different companies to maintain the same parameters for PCB quality assurance and reliability so that they can meet the expectations of the customers along with the improvement in the production process in many different ways

The IPC standards support PCB manufacturers in many ways like

Maintaining End product Quality and Reliability: The IPC standards will help the manufacturers build products with improved quality and reliability. When the Manufacturer maintains the Standards from the first step of the manufacturing process the end product will have the ability to perform better and lasts longer. The quality and reliability of the product should be maintained to compete in the electronics industry, so the manufacturers should always maintain these two factors.

Maintaining Consistency: Maintaining the consistency in quality and other parameters is the toughest task for the manufacturers. By maintaining the IPC certification the PCB manufacturers can maintain their consistency and which ultimately leads to customer satisfaction.

Better Communication: The IPC standards make sure that the same language has been used both internally and externally to define the terminologies associated with the life cycle of an electronic device, which reduces the risks of miscommunication too. With IPC standards the customers, suppliers, vendors, regulators, and others involved in the process will be having better communication with one another.

Maintains the Reputation: The IPC is an internationally recognized standard, hence it is known by each and every individual in the electronics industry. If you employ a new individual who doesn’t know anything about your company and if you have followed the IPC standard in your industry he/she can surely follow your reputation without any difficulties. Hence this process will enhance the quality of your product and improve your reputation so that you will be able to attract more customers towards your product.

Cost Reduction: When you follow the IPC standards in each and every step of the manufacturing process the end product will be in better quality and it will also be reliable to use, hence there is no need to do quality checks for each and every product once it is manufactured, this will reduce testing costs. Since everyone within the process is using the same terminologies for communication the possibilities of delays and reworks due to miscommunication also decrease, delays and reworks also cost the company.

Classes of electronics based on IPC Standards

According to the IPC standards, all electronic products are categorized under three different classes.

Class 1 (General Electronic Products)

The Class one products are the general electronics products that we use every day, the primary requirements of this product are the function they deliver. As the end product operation is more important this class is considered to be one of the most lenient classes when it comes to allowing potential defects. The PCB boards mostly do not fall under Class 1. The class 1 electronics usually have a shorter life cycle, the best example of a class 1 product is a flashlight.

Class 2 (Dedicated Service Electronics products)

The Products that require continued performance and extended life will fall under this class. Products under this class mainly focus on uninterrupted services, hence they make sure these products didn’t get failures during the operation. Some of the best examples of Class 2 Electronics are the Motherboard of a computer or a tablet, Circuit Boards in home appliances like television, Air conditioner, etc.

Class 3 (High-Reliability Electronic Product)

Class three electronics are of high standards which are meant for the critical application. The devices under this class should provide continuous performance or performance on demand. The class 1 electronics are usually cheaper and easily replaceable and the class 2 electronics are devices that require a long life cycle whereas the class 3 electronics are mission-critical items. The best examples that describe the class three electronics are the pacemaker and the military radar, which are needed to be highly reliable and ensure uninterrupted delivery of services.

Conditions used in IPC for refining a Product

Target Condition: This is the near-perfect condition that all the manufacturers will be aiming to achieve even this condition might not always be achieved.

Acceptable Condition: This is not the ideal condition accepted as there could be trade-offs between design and performance, but this condition delivers great reliability.

Defect Condition: If the Product is in defect condition it will be rejected as it needs to be reworked or repaired.

Process Indicator Condition: There are certain conditions that do not affect either the form or function of the product, but this condition will be available in the product due to the material, design or machine-related factors.

Some of the commonly used IPC standards

IPC-2581: It is the standard used for sending information between a PCB designer and a manufacturer or assembly company. It helps in delivering a standardized format for exchanging design data that help to ensure consistent production results.

IPC-2221: It is the standard that is used for designing the PCBs, this standard addresses the topics associated with the designing of a PCB such as design, layout, materials, mechanical and physical properties, electrical properties, thermal limitations, parts list and more.

IPC-6012B: It establishes the qualification and performance required for the fabrication of rigid PCBs. It delivers the requirements for the products in areas such as structural integrity, solderability, and conductor spacing.

IPC-A-600F: It sets up the acceptable criteria for the PCBs, it describes what is the target condition of the PCB and what are the conditions acceptable and non conforming for all the parts of the PCB. It describes everything from gold fingering to copper plating.

IPC-TM-650: IPC has published the test methods for PCB boards under IPC-TM-650, It provides the guidelines for assessing various aspects of PCBs. It provides the test methods for testing a board’s propensity for surface electromagnetic migration, measuring resistance to the flow current across a PCB substrate surface, methods for ionic cleanliness testing and more.

Apart from these standards, there are many more standards for each and every aspect of PCB board designing even the most minute aspects that you couldn’t even imagine. All these stands focus on delivering better electronic products that are reliable to be used.